Choosing the Right Table Saw Blade - Beginner Woodworking

This video goes over the basics of choosing the right table saw blade for your needs as a woodworker. For the begging woodworker choosing the right table saw blade can be a bit confusing so we are going to go over a few basics to help you choose the right one for your projects and table saw.

If you like this video please click here to subscribe to my channel

List of tools used in this tutorial:

Prestige Series General Purpose Blade Full Kerf

Prestige Series Ripping Blade Full Kerf

Choosing the Right Saw Blade for Your Projects and Table Saw

Hey folks, welcome back to Penalty Box Woodshop. Today we are gonna go over the basics of choosing the right table saw blade for your needs as a woodworker.

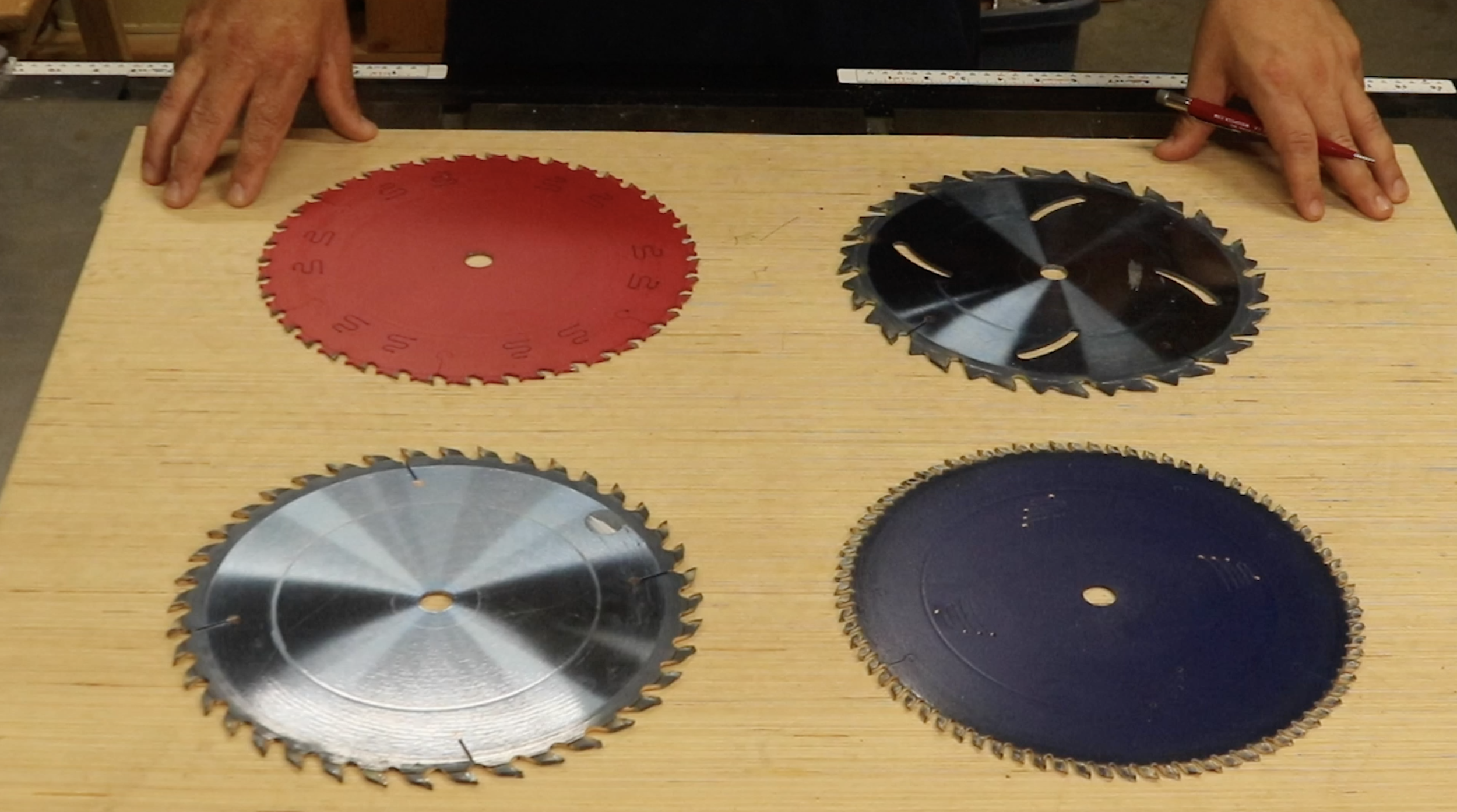

No matter what level of woodworking you’re in to its inevitable that at some point you’ll be shopping for a new table saw blade. The blades that come in saws straight from the box can be mediocre at best and it will not take long for you to realize that it’s time for an upgrade. For the begging woodworker choosing the right table saw blade can be a bit confusing so today we are going to go over a few basics to help you choose the right one for your projects and table saw.

Full Kerf and Thin Kerf Blades

The first thing we are going to discuss is the difference between a full kerf and thin kerf blade. That can sound like a confusing term but it’s just referencing to the width of the carbide tips which come in two standard sizes. A full kerf blade is 1/8” wide and a thin kerf blade is 3/32” wide.

Full kerf blades are of course wider and removes more material when it cuts through the wood. These are typically used on larger table saws because it takes a little more muscle from the operator and table saw motor to force the blade through the wood.

Thin Kerf blades remove less material and are better for smaller table saws because its easier to push through the material without putting a strain on your table saw motor. Thin kerf blades are typically the better choice for the every day woodworker using a contractor size table saw.

If you’re asking yourself why anyone would ever go with a full kerf blade its because they will stay sharper longer because of the larger carbide teeth and that’s important if your using the blade a lot.

Ripping Blades

Now, let’s talk about the most common types of blades used by the everyday woodworker.

Ripping blades typically have around 24- 30 teeth with large gaps between each tooth. These blades are used when making ripping cuts along the long edge of a board. A good ripping blade will leave a nice clean edge for glue edges when making panels.

The gaps between the teeth are called gullets and allow the blade to move the fibers as it cuts through the material.

The little knobs behind the carbide tips are anti kickback teeth that help prevent kickback when making the long cuts.

Crosscut Blades

Crosscut blades typically have around 60-90 teeth and as you can see here they have little space between each tooth. These blades are for making cross cuts across the grain of your boards. The excess number of teeth help prevent tear out and are great for when you’re making repeated cross cuts with your cross cut sled.

General Purpose and Combination Blades

Combination blades usually have around 40-50 teeth and will do both rip cuts and cross cuts. These blades are not going to do as good of a job as the two dedicated blades for these cuts but work fine for all around woodworking and if the budget just isn’t there for multiple blades. I typically leave my general purpose blade in my saw for everyday use but will switch it out for either the cross cut or ripping blade when I start a project that will need an abundance of these cuts.

Are the Expensive Blades Worth It?

Saw blades can run from anywhere between $30-$200 and trust me you get what you pay for. If you’re asking if the higher quality blades are worth it in the long rung the answer is pretty much always yes. The higher quality blades stay sharper longer and can be resharpened instead of just replacing it. Once you go through two or three lower quality blades you realize that you could have just bought a better one and saved money. I know that your particular budget will be the deciding factor but I would suggest you try to go with the highest quality blade that you can afford.

This is not a sponsored video and there a ton of great quality blades out there so do your research and ask other woodworkers what they prefer. I prefer and really like these Amana Tool Prestige Series blades and I’ll put a direct link to all the blades I show in this tutorial so that you can check them out if you like and see the cost differences in them.

Alright folks that does it for the basics of table saw blades and I hope this video is helpful for when it comes time to make that purchase.